Jester896

Senior Clown

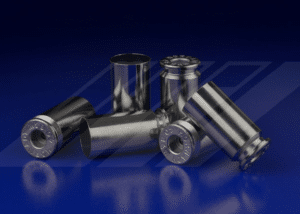

I have had a couple questions about reloading nickle cases recently, especially on annealing them, and I thought it might be a good idea to get some thoughts on it from everyone.

I use them in pistol loads for stuff I put up, for the corrosion resistance and a few rifle cases for the same reason. And not so much after a second firing.

I have seen things written about annealing them. Like the 2 materials need to be annealed to different temperatures...600 for the brass and 800+ for the nickle then quenched. Some say it causes the nickle to come off of the case case neck in a short time. Also that the nickle acts as a sandpaper on the inside of the neck when the bullet is released. I guess the best way to determine that for sure is to pull a bullet from a brass case and one from a nickle case to see the differences in markings on the pulled bullet

Also seen... for the most part...you usually only get 5-8 reloadings before the necks start to split

What are some of your thoughts on this?

I use them in pistol loads for stuff I put up, for the corrosion resistance and a few rifle cases for the same reason. And not so much after a second firing.

I have seen things written about annealing them. Like the 2 materials need to be annealed to different temperatures...600 for the brass and 800+ for the nickle then quenched. Some say it causes the nickle to come off of the case case neck in a short time. Also that the nickle acts as a sandpaper on the inside of the neck when the bullet is released. I guess the best way to determine that for sure is to pull a bullet from a brass case and one from a nickle case to see the differences in markings on the pulled bullet

Also seen... for the most part...you usually only get 5-8 reloadings before the necks start to split

What are some of your thoughts on this?