Twenty five ought six

Banned

I've been studying up some, which is always a dangerous thing. I ran across the book The Art of Making Fermented Sausages, by Stanley and Adam Marianski. The book documents and explains how to make traditional fermented sausages -- sausages which are allowed to "ripen" and not fully cooked. The most familiar ones would be salami, pepperoni, Lebanon baloney, and traditional summer sausage.

You can read most of the book here. It's very technical, and much more than a cookbook of recipes.

http://www.amazon.com/Art-Making-Fermented-Sausages/dp/1432732579#reader_1432732579

Basically, there are two ways to produce a sausage which is shelf stable but doesn't require cooking -- a fermentation process that lowers the pH of the meat to a level where the bad bacteria can't survive, or lowering the water content to a level where the bad bacteria can't survive, or a combination of both. Folks have been doing these for thousands of years-- the problem being that the process is hit or miss as to whether the meat can be "cured" before it spoils.

Recently, starter cultures have become available to the home sausage maker that allows him to produce a shelf stable, traditionally fermented, aged sausage without using the complex controlled environment equipment that commercial processors use. These starter cultures are basically the same, and the process is the same as producing wine or cheese, so it's not a bizarre process.

The Marianski book is based on the use of these cultures, which are produced by the Chr. Hansen company, and which are available from Allied Kenco among others. The particular culture I used is call LHP (have no idea why). You can read the details about what it is and what it does here.

http://www.meatprocessingproducts.com/19007.html

To keep it simple, I decide that my first project will be a summer sausage -- I know what it is, there is a commercial blend from Legg's, whose products I've found to be excellent, and summer sausage is a "fast fermented" product, which mean I can make it with a minimum of fuss and equipment.

And so I start.

I have a 16 lb. chub of ground pork that I am going to use. The Legg seasoning is for 25 lbs, so I have to come up with that much meat. I hold out 2 lbs. for breakfast sausage, so I end up with 14 lbs.. of pure pig.

To make up my 25 lbs. I root around in the freezer and come up with 11 lbs. of various cuts of deer. If I had been a serious sausage maker, I would have used about 7 lbs.of venison, and 4 lbs. of fat, but this particular batch of pork is plenty fatty.

I might note that because this fermentation process relies on the growth of "good" bacteria, you want to minimize the chance the growth of "wild" bacteria --anyone who has every made beer knows what I mean. So before I start, I wash my grinder, cutting board, and everything in a bleach solution -- then I do something I don't normally do;

Even though the pork is ground, I want a finer grind, so through the grinder it goes.

As I grind the pork, I drop in the pieces of the semi-frozen venison. When I get through, I have 25 lbs. of ground meat -- you can see the redder venison among the pork

Next I prepare my seasonings and cure --

Legg's Summer Sausage Seasoning

Leggs No. 1 cure (aka "Prague No. 1")

I put these in water so that they are evenly distributed. The package recommends 3 lbs. of water (and a pint's a pound the world around). I wouldn't use that much water again. There was no harm in doing so -- just extends the drying process. On the label, not that it refers to a "reduced pH product", and to adjust procedures accordingly, so that's one adjustment I'll make.

Now I plug in the automatic mixer, and thoroughly mix everything up --

Switch the mixer over to "high"--

Here's where I deviate from the book some. Traditionally sausage would be allowed to cure for a day or two in a cooler. The book says not to do this because it allows the nasties to grow. Well, I did it any way. I needed to cool the meat off again, and I was tired, and I really didn't think it would hurt -- so back in the Frigidaire overnight.

Next day, prepare to add the culture --

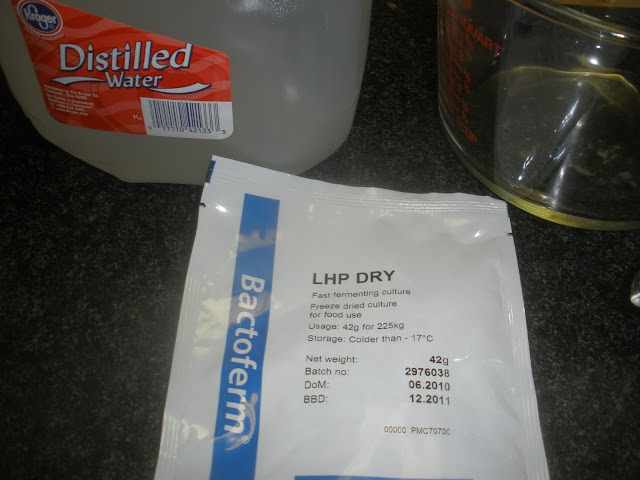

Have to use distilled water (or well water I suppose) because the chlorine will kill the culture (just like making bread)--

Culture --note that package does 400 lbs.

Culture in distilled water, doing it's thing. I let it sit about a half hour to "wake up,"

Lay out my casings. These are collagen casings, which is a natural product, and each casing will hold approx. 1 1/2 lbs. of sausage.

Sausage meat (forcemeat if you want the correct name) with the culture added,

Load up the stuffer. Run out some sausage. If you don't do this, the stuffer will pump air into your casing, and you don't get a good "pack".

Just like slipping on a, uh, never mind -- casing ready to fill.

Filled casing.

Four in a row. Leave a little tail on the casing for hog ring place later. my stuffer is 5lbs. and would fill exactly 4 of these casings --so that worked out nicely.

Eight in a row --

Now for a brief interlude from the slide show. This particular culture requires a fermentation period of 24 hours at 100 deg. F. I had tested my "blue cube" with a 40 watt shop light in it for a couple of days, and it seemed to be holding a temp in this range. So I put the sausages on rod and hung them in the Blue Cube with the shop light. You also have to maintain a 95% relative humidity, which I did by soaking a bathmat (clean one ) in water, and laying in the bottom of the Blue Cube. Problem is that the temp shot way up. I'm not sure why. Problem is that if the temp gets too high, it will kill the good bacteria.

) in water, and laying in the bottom of the Blue Cube. Problem is that the temp shot way up. I'm not sure why. Problem is that if the temp gets too high, it will kill the good bacteria.

So I pulled out the shop light, and inserting two gallon jugs with 115 deg. water from the tap. 115 deg. is still within the safe range. It took about 8 hours for the temp to fall to 90 deg., I refilled the water, and started over -- at the end of the day every thing seem to work out as the sausages were obviously sweating, and had lost some weight.

The next step is sort of testy from the low tech approach. You are supposed to hold the sausages at 75 deg. at a declining humidity from 85% down. The temp isn't that big a problem, but for the home operator, controlling the humidity is a bear. The authors of the book acknowledge this is the hard part, mostly because there is no easy way for Joe Dokes to measure the average humidity.

As it happen about that time we had a rainy, cold weekend, and so I took the real low tech solution and hung every thing in the garage. I wipe everything down once a day with a wet paper towel.

My "fermentation chamber" in my garage. Basically, I raised the garage door during the day, and closed it at night.

If you are into sausage trivia, note that some of the sausages have already lost a substantial amount of weight (top of the casings) but that they casings are clinging to the meat as it cures --- which is a very very good thing.

More fermentation in the garage, and you can see how much loss from drying out there is. On some of them, I have forced the sausage up into the casing, so that the "tail" is at the bottom.

After about 4 days of fermenting in the garage, we move the sausages to my smoker. I make up a rack to hang them with.

I start with two days of cold smoke --smoke that doesn't exceed 75 deg. Again I was greatly assisted by a cold snap that kept the ambient temps low.

Then I gradually raised the smoking temp to 140 deg. I'm using my BBQ smoke which is a propane gas cylinder. I didn't fully appreciate the temp differential in the bottom and top of the cylinder (which is laid horizontally), and in the following picture, you can see that the sausage got substantially hotter than lower down. That's something I'm going to have to work on. About 6 hours of "hot" smoke" . Overall, there is good smoke, good appearance, and good cling from the casing. Note that the sausage is never "fully" cooked.

In the following picture you can really see how much has sweated out -- explains why real smoked product costs so much. Loss approaches 30%

Close up of links in the smoker showing details of the smoking process --

This picture was taken March 10, 2011 -- more on that-- for all intents and purposes that fermentation and smoking process is over.

When you get through, the fermentation process has lowered the pH. I didn't test the pH, other than taste test. The lower pH results in a "tangy" taste that is connected with quickly fermented American style sausage, particularly summer sausage. (For the real wonks, summer sausage and Lebonon Bologna are essentially the same thing, except that Lebonon bologna is all beef).

I thought the taste was a little too tangy or sour. This may have been due to the high initial fermentation process, but more on that later.

Here is the finished product. The pink color is considered "good" for cured meat, and highly desirable. Indicates that the meat has been properly cured.

Now about the too tangy issue -- these pictures were taken today, April 3, 2011. The sausage has continued to hang in my garage, due to the relatively low temps. So with roughly three weeks additional hang time, the sausage has mellowed out considerably -- it's still plenty "tangy" but not objectionably so.

On the really warm days, they will sweat a little fat, which in not good, but doesn't seem to hurt. No mold or other adverse issues. So the goal of producing a shelf stable cured product has been obtained.

Here is my personal "charcuterie", and you can see that the loss definitely somewhere greater than 30% (which is expected). On most of the sausages, the fill of the casing is good, and the casing has done what it is supposed to by clinging to the meat as it dries. You can get a real goof idea of the loss from the sausage in the middle with the string tied around it -- that casing was totally packed when we started.

The sausage on the right shows evidence of getting too hot in the smoker on the upper end. That's a result of using horizontal heat, instead of vertical heat -- and my not properly monitoring the top of the smoker. (Heat rise --doh!_ ). This part of the meat is edible, just a little dry from having most of the water and fat cooked out.

). This part of the meat is edible, just a little dry from having most of the water and fat cooked out.

Note that although no more smoke has been applied the sausage has continued to darken-- which I attribute to a chemical reaction with the smoke and aging.

I want to put in a shameless plug for Legg's -- the people who made the seasoning package. I had a couple of technical questions before I started out, and shot them out an e-mail. They didn't know me from Adam's house cat, but in both instances received a complete and thorough answer within 24 hrs.-- actually was within 8 hrs. I think. Legg's is an Alabama company.

You can read most of the book here. It's very technical, and much more than a cookbook of recipes.

http://www.amazon.com/Art-Making-Fermented-Sausages/dp/1432732579#reader_1432732579

Basically, there are two ways to produce a sausage which is shelf stable but doesn't require cooking -- a fermentation process that lowers the pH of the meat to a level where the bad bacteria can't survive, or lowering the water content to a level where the bad bacteria can't survive, or a combination of both. Folks have been doing these for thousands of years-- the problem being that the process is hit or miss as to whether the meat can be "cured" before it spoils.

Recently, starter cultures have become available to the home sausage maker that allows him to produce a shelf stable, traditionally fermented, aged sausage without using the complex controlled environment equipment that commercial processors use. These starter cultures are basically the same, and the process is the same as producing wine or cheese, so it's not a bizarre process.

The Marianski book is based on the use of these cultures, which are produced by the Chr. Hansen company, and which are available from Allied Kenco among others. The particular culture I used is call LHP (have no idea why). You can read the details about what it is and what it does here.

http://www.meatprocessingproducts.com/19007.html

To keep it simple, I decide that my first project will be a summer sausage -- I know what it is, there is a commercial blend from Legg's, whose products I've found to be excellent, and summer sausage is a "fast fermented" product, which mean I can make it with a minimum of fuss and equipment.

And so I start.

I have a 16 lb. chub of ground pork that I am going to use. The Legg seasoning is for 25 lbs, so I have to come up with that much meat. I hold out 2 lbs. for breakfast sausage, so I end up with 14 lbs.. of pure pig.

To make up my 25 lbs. I root around in the freezer and come up with 11 lbs. of various cuts of deer. If I had been a serious sausage maker, I would have used about 7 lbs.of venison, and 4 lbs. of fat, but this particular batch of pork is plenty fatty.

I might note that because this fermentation process relies on the growth of "good" bacteria, you want to minimize the chance the growth of "wild" bacteria --anyone who has every made beer knows what I mean. So before I start, I wash my grinder, cutting board, and everything in a bleach solution -- then I do something I don't normally do;

Even though the pork is ground, I want a finer grind, so through the grinder it goes.

As I grind the pork, I drop in the pieces of the semi-frozen venison. When I get through, I have 25 lbs. of ground meat -- you can see the redder venison among the pork

Next I prepare my seasonings and cure --

Legg's Summer Sausage Seasoning

Leggs No. 1 cure (aka "Prague No. 1")

I put these in water so that they are evenly distributed. The package recommends 3 lbs. of water (and a pint's a pound the world around). I wouldn't use that much water again. There was no harm in doing so -- just extends the drying process. On the label, not that it refers to a "reduced pH product", and to adjust procedures accordingly, so that's one adjustment I'll make.

Now I plug in the automatic mixer, and thoroughly mix everything up --

Switch the mixer over to "high"--

Here's where I deviate from the book some. Traditionally sausage would be allowed to cure for a day or two in a cooler. The book says not to do this because it allows the nasties to grow. Well, I did it any way. I needed to cool the meat off again, and I was tired, and I really didn't think it would hurt -- so back in the Frigidaire overnight.

Next day, prepare to add the culture --

Have to use distilled water (or well water I suppose) because the chlorine will kill the culture (just like making bread)--

Culture --note that package does 400 lbs.

Culture in distilled water, doing it's thing. I let it sit about a half hour to "wake up,"

Lay out my casings. These are collagen casings, which is a natural product, and each casing will hold approx. 1 1/2 lbs. of sausage.

Sausage meat (forcemeat if you want the correct name) with the culture added,

Load up the stuffer. Run out some sausage. If you don't do this, the stuffer will pump air into your casing, and you don't get a good "pack".

Just like slipping on a, uh, never mind -- casing ready to fill.

Filled casing.

Four in a row. Leave a little tail on the casing for hog ring place later. my stuffer is 5lbs. and would fill exactly 4 of these casings --so that worked out nicely.

Eight in a row --

Now for a brief interlude from the slide show. This particular culture requires a fermentation period of 24 hours at 100 deg. F. I had tested my "blue cube" with a 40 watt shop light in it for a couple of days, and it seemed to be holding a temp in this range. So I put the sausages on rod and hung them in the Blue Cube with the shop light. You also have to maintain a 95% relative humidity, which I did by soaking a bathmat (clean one

So I pulled out the shop light, and inserting two gallon jugs with 115 deg. water from the tap. 115 deg. is still within the safe range. It took about 8 hours for the temp to fall to 90 deg., I refilled the water, and started over -- at the end of the day every thing seem to work out as the sausages were obviously sweating, and had lost some weight.

The next step is sort of testy from the low tech approach. You are supposed to hold the sausages at 75 deg. at a declining humidity from 85% down. The temp isn't that big a problem, but for the home operator, controlling the humidity is a bear. The authors of the book acknowledge this is the hard part, mostly because there is no easy way for Joe Dokes to measure the average humidity.

As it happen about that time we had a rainy, cold weekend, and so I took the real low tech solution and hung every thing in the garage. I wipe everything down once a day with a wet paper towel.

My "fermentation chamber" in my garage. Basically, I raised the garage door during the day, and closed it at night.

If you are into sausage trivia, note that some of the sausages have already lost a substantial amount of weight (top of the casings) but that they casings are clinging to the meat as it cures --- which is a very very good thing.

More fermentation in the garage, and you can see how much loss from drying out there is. On some of them, I have forced the sausage up into the casing, so that the "tail" is at the bottom.

After about 4 days of fermenting in the garage, we move the sausages to my smoker. I make up a rack to hang them with.

I start with two days of cold smoke --smoke that doesn't exceed 75 deg. Again I was greatly assisted by a cold snap that kept the ambient temps low.

Then I gradually raised the smoking temp to 140 deg. I'm using my BBQ smoke which is a propane gas cylinder. I didn't fully appreciate the temp differential in the bottom and top of the cylinder (which is laid horizontally), and in the following picture, you can see that the sausage got substantially hotter than lower down. That's something I'm going to have to work on. About 6 hours of "hot" smoke" . Overall, there is good smoke, good appearance, and good cling from the casing. Note that the sausage is never "fully" cooked.

In the following picture you can really see how much has sweated out -- explains why real smoked product costs so much. Loss approaches 30%

Close up of links in the smoker showing details of the smoking process --

This picture was taken March 10, 2011 -- more on that-- for all intents and purposes that fermentation and smoking process is over.

When you get through, the fermentation process has lowered the pH. I didn't test the pH, other than taste test. The lower pH results in a "tangy" taste that is connected with quickly fermented American style sausage, particularly summer sausage. (For the real wonks, summer sausage and Lebonon Bologna are essentially the same thing, except that Lebonon bologna is all beef).

I thought the taste was a little too tangy or sour. This may have been due to the high initial fermentation process, but more on that later.

Here is the finished product. The pink color is considered "good" for cured meat, and highly desirable. Indicates that the meat has been properly cured.

Now about the too tangy issue -- these pictures were taken today, April 3, 2011. The sausage has continued to hang in my garage, due to the relatively low temps. So with roughly three weeks additional hang time, the sausage has mellowed out considerably -- it's still plenty "tangy" but not objectionably so.

On the really warm days, they will sweat a little fat, which in not good, but doesn't seem to hurt. No mold or other adverse issues. So the goal of producing a shelf stable cured product has been obtained.

Here is my personal "charcuterie", and you can see that the loss definitely somewhere greater than 30% (which is expected). On most of the sausages, the fill of the casing is good, and the casing has done what it is supposed to by clinging to the meat as it dries. You can get a real goof idea of the loss from the sausage in the middle with the string tied around it -- that casing was totally packed when we started.

The sausage on the right shows evidence of getting too hot in the smoker on the upper end. That's a result of using horizontal heat, instead of vertical heat -- and my not properly monitoring the top of the smoker. (Heat rise --doh!_

). This part of the meat is edible, just a little dry from having most of the water and fat cooked out.

). This part of the meat is edible, just a little dry from having most of the water and fat cooked out. Note that although no more smoke has been applied the sausage has continued to darken-- which I attribute to a chemical reaction with the smoke and aging.

I want to put in a shameless plug for Legg's -- the people who made the seasoning package. I had a couple of technical questions before I started out, and shot them out an e-mail. They didn't know me from Adam's house cat, but in both instances received a complete and thorough answer within 24 hrs.-- actually was within 8 hrs. I think. Legg's is an Alabama company.